Delivering small-lot-mass-production plastic parts at reasonable prices.

Please contact us for small-lot plastic molding, mold production, or anything else.

We deliver high quality parts to the world with quick delivery.

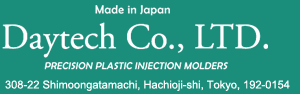

Daytech Co,Ltd. is located in Tokyo, Japan, developing "prototype plastic injection molds" and supplying plastic parts for electronics, medical industries and household-appliance industries, especialy for R&D divisions.

One of our best practice of plastic injection molds is creating molds by Alminum such as Al7075S. We cut alminum plastic molds directory. By doing so, the molds are precise and small-sized, and it benefitial for companies which aim to develop small lot of precision plastic parts.

Prototype molds are not plastic injection molds that can be used only for prototyping. With our unique technology, we can use prototype molds for injection molding from prototypes to small-lot mass production with the same quality as mass production. Small-lot mass production is possible for 100 to 5,000 units, depending on the shape, and we have experience with up to 10,000 units.

Quick response to injection molding from one piece under various conditions

We have been involved in small-lot injection molding since early on, and we can use our experience to respond quickly to the needs of R&D departments. We manufacture prototype molds using aluminum material (A7075S) with excellent machinability.

Solving the problem of small-lot plastic parts.

When making prototypes or small-lot mass production of plastic parts, it is necessary to create molds if you want to make prototypes using the same materials and molding conditions as the actual production. However, the cost of molds is very expensive. Our prototype molds address such problems.

- Initial costs are too high to create a mold for small-lot plastic parts for prototyping and R&D.

- We would like to create parts under the same injection molding conditions as in the production environment, even for prototypes, rather than using cutting processes.

- Prototype molds from other companies are not accurate enough and cannot be used for mass production.

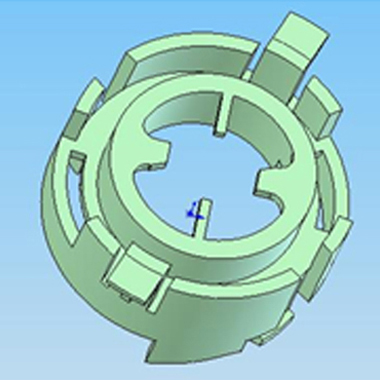

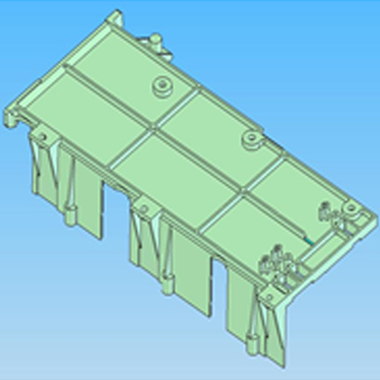

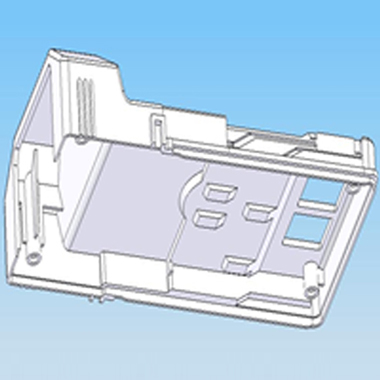

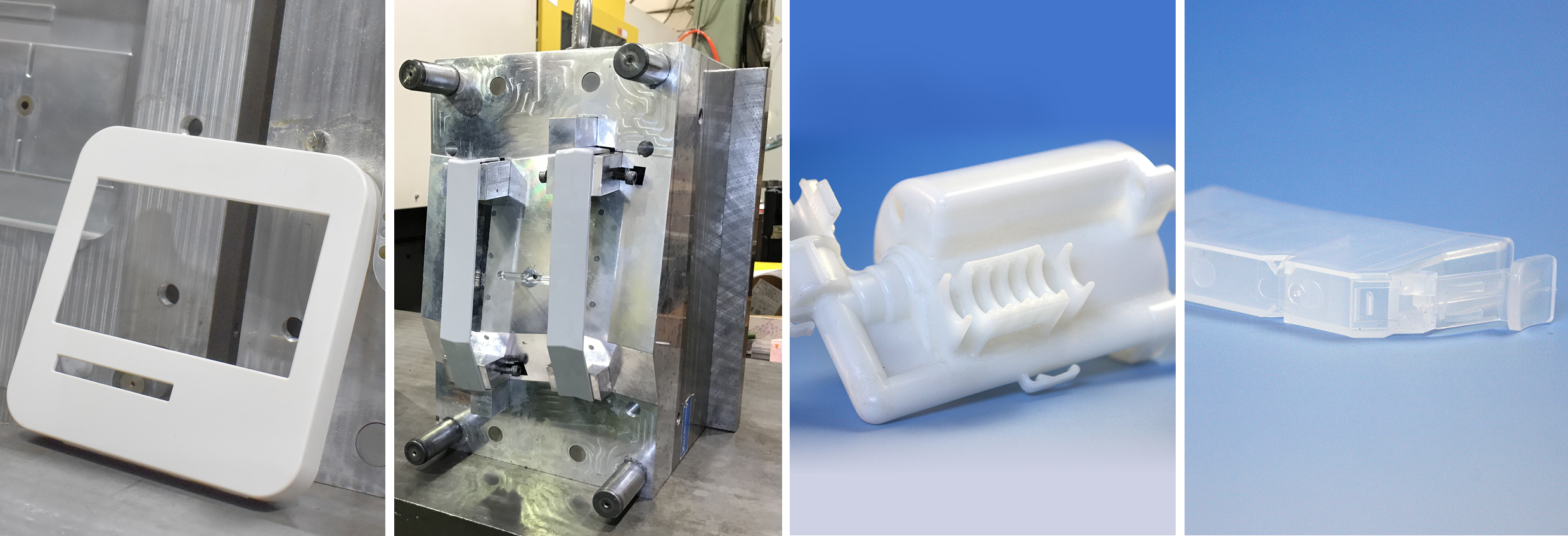

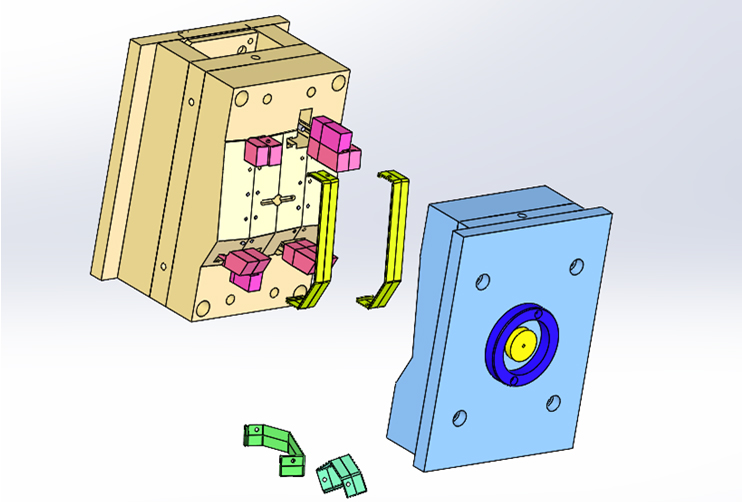

The mold base is our original "cassette type", and the slide mechanism is supported by the placement piece. Aluminum (7075S) is used for the cavity, core, and base. As a result;

- Complex shapes, including undercuts, can be handled by placing pieces.

- The mold can be downsized to save cost.

- The shape of the mold can be changed by changing the placement piece.

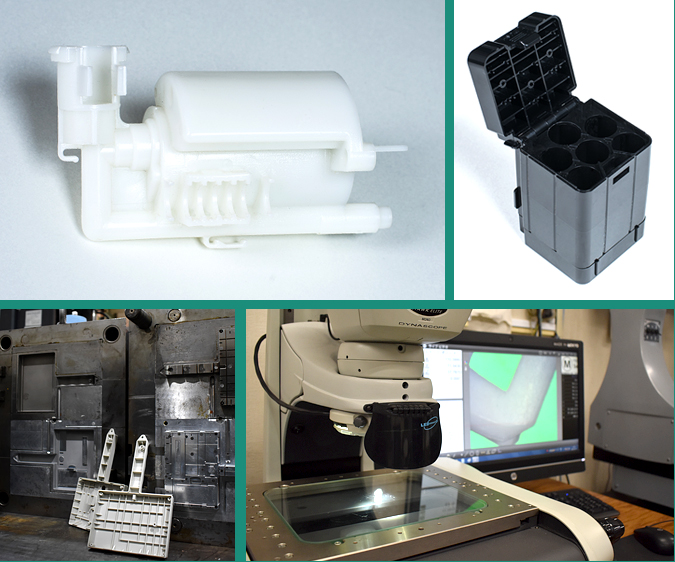

One-stop service from material arrangement to injection molding.

We can also design plastic parts. If you provide us with specifications and drawings, we can provide a one-stop service from material arrangement to design, prototyping, mold making, and injection molding.

- We can provide dimensional measurements and geometric tolerances.

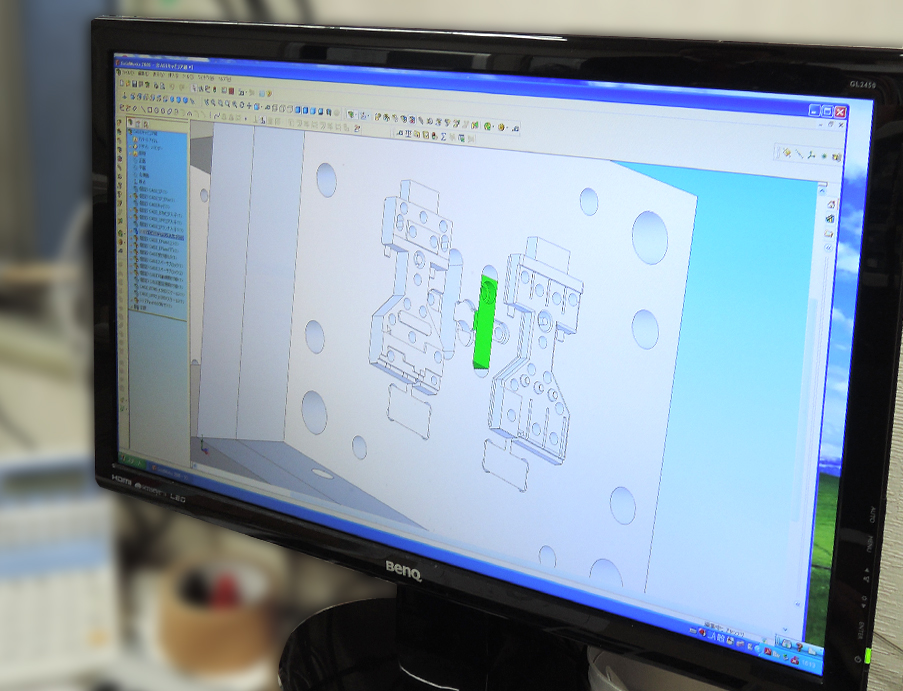

(CAD)SolidWorks、spaceE、inventor

Prototype plastic injection molds

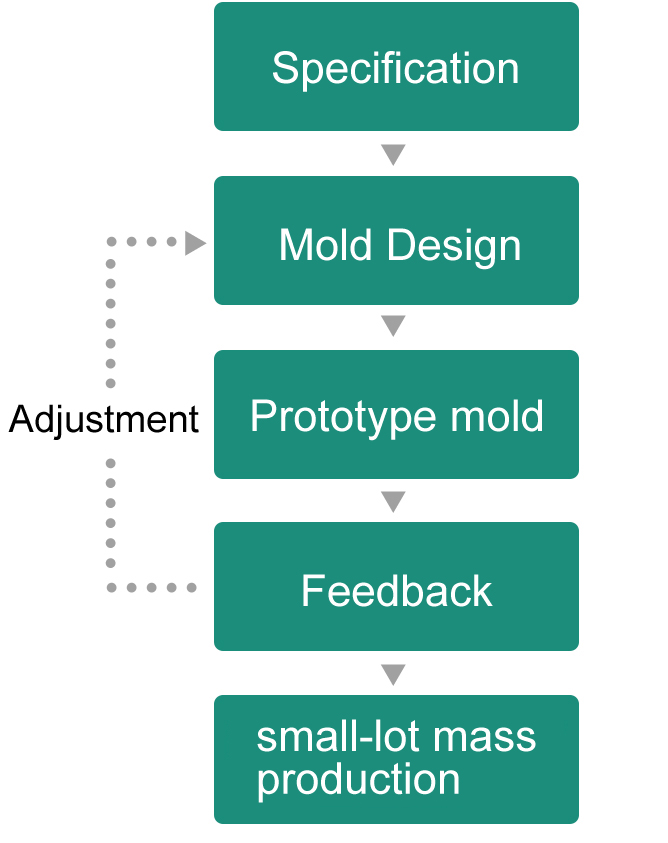

| General | Our technology | |

| Usage | Prototyping(Test pieces before mass production) | Prototyping and reliability test at development phase. Small lot mass production. |

| Material | Steel, NAC80, etc. | A7075S, depending on the usage. |

| Possible number of shots | 500-1500 | 10,000 shots, depending on the shape. |

| Supported plastic materials | Mainly general-purpose plastic. | Aslo handle engineering plastics. |

| Supported plastic shape | Simple shape. | Complex shapes are available. |

| Supported surface treatment | Limited. | Wide variety of options. |

Business guide

-

Mold design and fabrication

By using placement pieces for prototype molds, we can design complex molds in a short period of time.

more

-

Cutting process

We can process even plastic and metal materials that are difficult to cut.

more

-

Injection molding

It is also possible to change from cutting to injection molding.

more

-

Restoration of discontinued items

We can accurately restore maintenance parts and obsolete products.

more

-

Electrical discharge machining

Electrical discharge machining is used for finer and more precise processing.

more

-

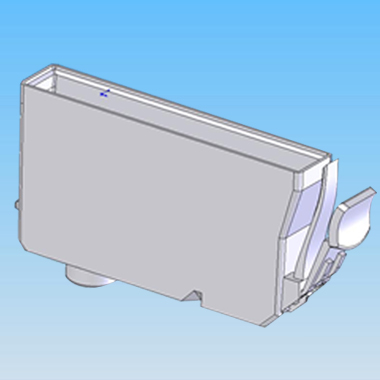

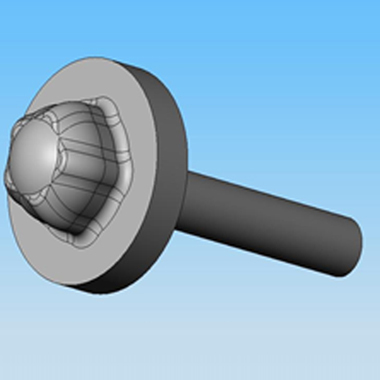

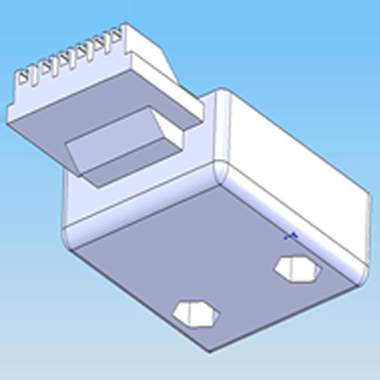

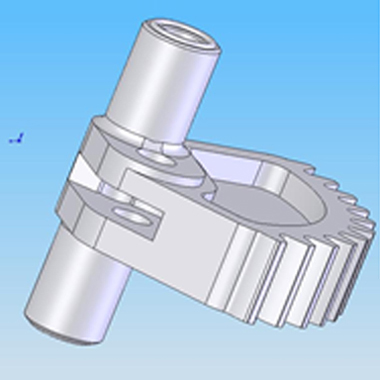

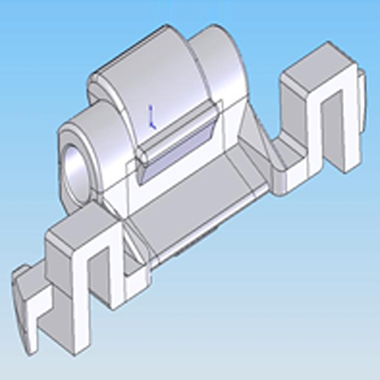

Processing examples

Here are some examples of our experience in processing plastic products.

more

Topics

- 2022.03.28 blog Secondary processing【Introduction of parts machining】

- 2022.03.28 blog Design design, mold fabrication, and molding

- 2022.02.21 blog Prototype mold, aluminum mold mechanism