Smooth transition to mass production with a mold equivalent to the mass production mold

Depending on the shape of the molded product, up to 10,000 shots can be molded by using the material A7075S for the mold making. It is possible to smoothly transit from prototype to mass production as the injection molding can be performed using the same materials as in the mass production.

-

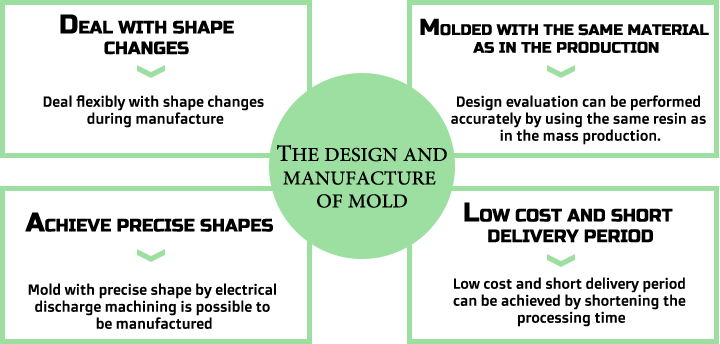

About the design and manufacture of prototype molds

“Molds” manufactured by Daytech are not so-called “test molds”

-

Support small lot production! Prototype mold technology

We can flexibly handle cassette type, placement pieces and shape changes with aluminum molds.

Deal with precise and complex shapes

Making precise and complex shapes is possible as the materials being used feature the quality and accuracy (from ± 0.02 to ± 0.05), and are extremely excellent in the properties for the processing, such as cutting, discharging, and polishing.