What is electrical discharge machining?

Electrical discharge machining is a method in which sparks are generated by electricity between the opposite metals in pure water or oil and the metals are melted by the heat for processing.

Electric discharge occurs at intervals of 1,000 to 100,000 times per second, and the metal is processed by repeating the processes of melting, cooling, and the dispersion of the metal.

Metals that are harder than the blade cannot be processed by normal cutting, but since electrical discharge machining applies the electrical energy for processing, the workpiece of any hardness, even ultra-hard metals can be processed. On the contrary, this method is not suitable for processing materials that do not conduct electricity.

In addition, electrical discharge machining can be used to process fine and complex shapes that are difficult to process with blades, and it is also frequently used for processing precision parts and molds.

Types of electrical discharge machining

There are two types of electrical discharge machining which are die sinking electrical discharge that transfers the electrodes and wire electrical discharge that uses thin metal.

Die sinking electrical discharge machining

Die sinking electrical discharge machining is a processing method in which the tool electrodes using copper or graphite are transferred to a workpiece by electrical discharge.

The biggest difference from wire-cut electrical discharge machining is that there is no need to make through holes in the workpiece, and pocket machining with bottom and deep groove machining are available.

It is possible to process the parts which cannot be reached by cutting tools and difficult for cutting processing, such as the complex shapes including thread cutting and spirals, and irregular shapes such as square holes and hexagonal holes.

Wire-cut electrical discharge machining

Wire-cut electrical discharge machining is a processing method in which the workpiece is cut while melting by the means of an electric current passing through the wire that serves as an electrode to discharge the electric current between the wire and the workpiece.

Most of the wires used are made of very thin brass with the thickness of about a diameter of 0.3mm. The workpiece can not only be cut with a flat surface, but also can be cut with an inclined surface.

Wire-cut electrical discharge machining is ideal for fine and precision processing such as the post-processing of gears, jigs and quenching, precision cutting and drilling of plate metal (brass plate, steel plate, copper plate, stainless plate, aluminum plate), as it is a non-contact processing.

Small hole discharge

Small hole electrical discharge machining is a processing method for machining small diameter holes. Holes are made in the workpiece using pipe electrodes and rod electrodes which match the hole diameter.

We can handle the processing with high accuracy from fine holes which are difficult for cutting to general holes.

The original electrical discharge machining developed by Daytech

Die sinking electrical discharge machining

Daytech uses two die sinking electrical discharge machines.

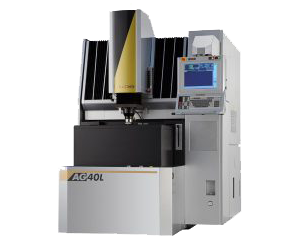

The first one is AG40L (made by Sodick)

Since the operating table is driven by linear motors, repeated operations of positioning can be performed accurately. Up to 16 electrodes can be mounted at one time with the ATC (Automatic Tool Change) mechanism, which enables the high-precision machining and the improvement of work efficiency.

The electrode is also manufactured with the tooling system of EROWA NIPPON Ltd, and complex shapes and precise shapes can be handled by the 3-axis and 4-axis machining centers.

Since the main spindle also rotates, it is possible not only to make molds but also to process various kinds of complex shapes such as twisted gears, helical gears and lead grooves which are difficult to cut.

The second one is DX45BNC (made by Sodick)

The electrical discharge machine is capable to handle large items owing to its 3-axis NC control system, an operating range of 600 x 400 and a powerful electric current of 50A.

We can meet the expectations of cost and quality by using multi-cavity electrodes even for mass electrical discharge machined parts.

Wire-cut Electrical discharge machining

We use AQ537L, the wire-cut electrical discharge machine made by Sodick. Since AQ537L uses a linear motor and a linear scale, it has excellent positioning accuracy and can perform the processing with 5 axes, which enable the processing of taper and vertical irregular shapes that are normally difficult to machine.

Small hole electrical discharge machining

As for the small hole electrical discharge machine, we use CDH-2A.

In the case of electricity is applied to drill the holes from a diameter from 0.4mm to 3mm, holes can be drilled in any metal without contact and can be connected by processing the metal block from multiple directions.

The start hole, which is absolutely indispensable for wire-cut electrical discharge machining, can be processed accurately, and it is also possible to make the defective products caused by the damage to the tap or drill to be a qualified one.

Examples of electrical discharge machining

The followings are the introductions of the examples of small hole electrical discharge machining, wire-cut Electrical discharge machining and die sinking Electrical discharge machining.

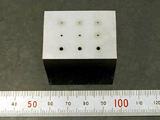

- Small hole electrical discharge machining

- Drill a cylinder with a diameter of 0.8mm using a wire electrical discharge machine

- Small hole electrical discharge machining

- Drill a processed item with a diameter of 0.8mm using a wire electrical discharge machine

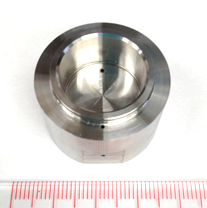

- Wire-cut electrical discharge machining

- The circumference is processed by lathe. The surface is drilled by wire-cut electrical discharge machining

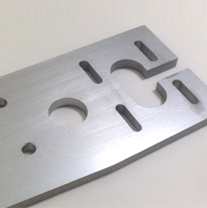

- Wire-cut electrical discharge machining

- Cut and drill by wire-cutting electrical discharge machining

- Die sinking electrical discharge machining

- Die sinking electrical discharge machining of the upper threaded part